Linkage-less Control Systems that Provide Complete Combustion Management

AUTOFLAME has a rich history, so it’s fitting that their offices would be located at London’s Biggin Hill Airport. Here, in the heart of the United Kingdom, is the WWII airstrip where there is no greater concentration of Spitfire activity in the world. During the Second World War, Biggin Hill acquired a reputation as the most famous fighter station in the world, primarily through its associations with the Battle of Britain and it being home to the US 133 Eagle Squadron.

With Biggin Hill as its backdrop, it’s not surprising that innovation and efficiency is at the core of all that AUTOFLAME produces. Beginning as a small business in 1968, AUTOFLAME was created by a Boiler Technician (BT), Brendan Kemp, who was frustrated from using the linkage controls.

Kevin Warren, Director of Sales for EEE and a retired United States Navy BT, said, “I’m not surprised that the AUTOFLAME controllers were the brainchild of a fellow BT. It is the most versatile and capable linkage-less control system.”

52+ years later, AUTOFLAME has more than 20,000 units currently in operation, dozens of OEM partners, and more than 100 Technology Centers worldwide. They have been recognized on three separate occasions with the Queen’s Award for Enterprise in the United Kingdom (UK).

Steve Kemp, Director of AUTOFLAME Engineering Limited, explained that they started as a burner service company that was striving to find a better way to control the right amount of fuel and air to the burner (fuel to air ratio control). “The change away from the linkage systems was partially determined by the change in the UK from oil to natural gas during the early 70’s. It was the transfer to natural gas that created the need,” said Kemp. He added that this change was very expensive, so there was a need to save fuel, costs, and emissions.

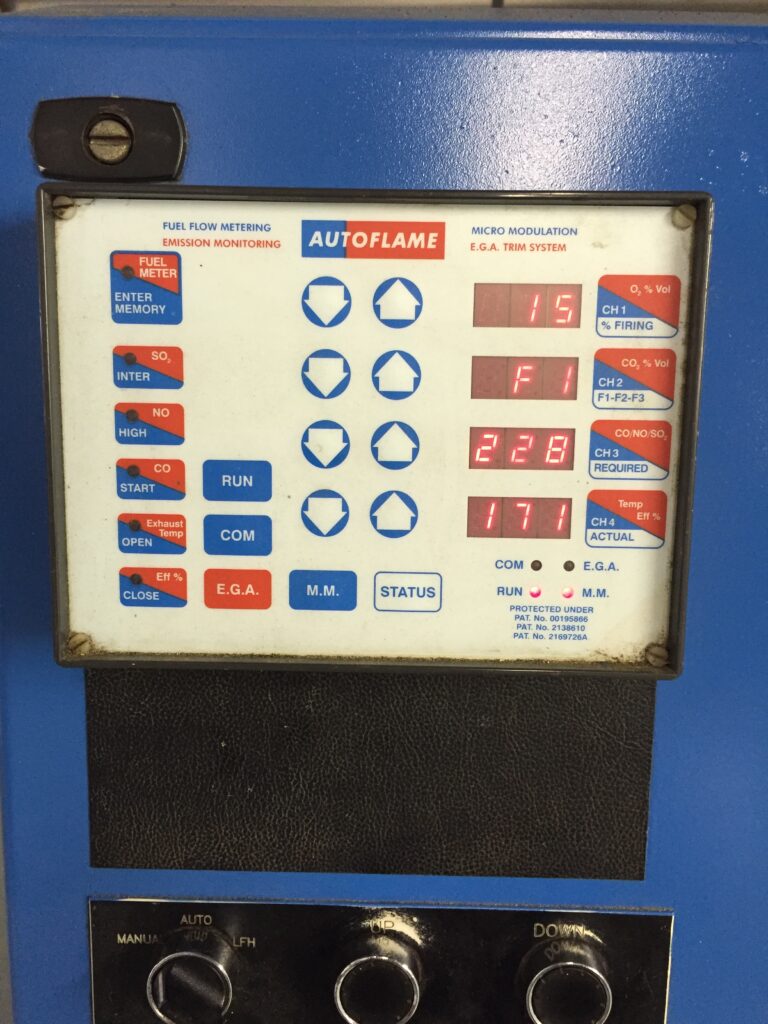

Kevin Warren noted that not only do the AUTOFLAME controllers reduce costs from fuel savings, but they are very durable. Pictured is one of the earlier generations of AUTOFLAME controllers that was manufactured on March 18, 1997 and later installed at Peace River Citrus. “And it’s still in commission today,” said Warren.

More than four decades (40+ years) later, EEE and their technicians work with the Mark 8 Controller that Warren refers to as, “…the best available technology.” Steve Kemp said, “The Mark 8 is now doing almost everything for the boiler…every day of the year we can maintain perfect combustion and optimum boiler efficiency.”

In that regard, AUTOFLAME controllers have significantly increased the safety in boiler rooms. With the addition of the Proportional-Integral-Derivative (PID) controller, a boiler’s pressure and temperature are also monitored. Later, draft control and water level control were added, so the Mark 8 now functions as a full level control.

Kevin Warren said that the fuel to air ratio provided by AUTOFLAME is highly accurate, “It’s 1/10th of one degree.” When asked who needs an AUTOFLAME Mark 8 controller, Warren said, “People looking for a very accurate combustion control system and who want to achieve maximum mechanical efficiency.”

Steve Kemp explained that the AUTOFLAME controllers are error checking constantly to ensure a safe operation. “We are error checking 50 times every second,” said Kemp.

Another feature of the Mark 8 Controller is that it is very “user friendly,” according to Warren. “The Mark 8 has a full-touch screen control, so people can see what’s going on, as opposed to the black box controlling the burner,” explained Kemp.

Whether a company is installing a new boiler or trying to increase the efficiency of an older burner, the AUTOFLAME Mark 8 is an enhancement. Kemp said, “We can only optimize what they can do. We can add to any combustion process that is mixing fuel and air.”

EEE also represents Webster Combustion Technology, one of the first companies in the U.S. to use the AUTOFLAME linkage-less technology. “The AUTOFLAME control system can be used on different types of burner systems. It is the controller of choice for Webster Combustion…But any burner using fuel and air can use our product,” said Kemp.

Because of its cost savings, emissions reduction, and safety profile, Kevin Warren said, “It’s the only control system EEE represents because of its reliability, functionality, accuracy, and efficiency.”

The Mark 8 Controller from AUTOFLAME is a Class 1 Safety Device with a complete burner management system and flame safeguard control. It monitors the burner as it goes through its startup process and as it continues to run.

To learn more about the importance and efficiency of linkage-less controllers and specifically the Mark 8 AUTOFLAME controller, call our experts at EEE at (863) 682-3333, or e-mail us at info@eeeinc.net.