Feedwater: Weathering The Storm, Part 2. The importance of water treatment.

Engineered Energy Equipment Provides Boilers, Burners, and Auxiliary Equipment in Florida

In the last Boilerman Blog, we outlined the effects that feedwater quality has on the efficiency, longevity, and safety of a boiler. Other environmental factors like heat, humidity, salt, and water intrusion make the purchase of a boiler in Florida and the selection of your boiler room technicians muis importanté!

“Water chemistry is one of the most important elements in maintaining a boiler,” said Kevin Warren, EEE Director of Sales. “You need a water softener no matter where you’re operating a boiler,” he added.

According to one of EEE’s water treatment providers, Sci Chem LLC, “…hard water is formed when water flows through the lime rock in our Karst topography and dissolves calcium and magnesium carrying it into our [facilities]. These minerals bind with metal, reducing the efficiency of [boilers] causing excessive wear to our water using [systems]. http://www.sci-chemllc.com/index.php/central-florida-water.html

Pre-Treating

Florida is not alone in its water quality problems. All fresh and natural water contain impurities. These impurities are critical factors when water is used for generating steam. Higher-pressure boilers require pre-treated water in order for them to function smoothly (with good thermal conductivity). For optimal efficiency, supply water to the boiler (feedwater) that you’ve pre-treated for removal of impurities to prevent scaling and corrosion.

You must pretreat by filtration and processes that include softening, ion exchange, evaporation, etc. Condition your boiler also to remove impurities. This prevents corrosion and regular inspections should be a part of standard boiler room operation. Annual maintenance should always include checking for signs of scaling and corrosion.

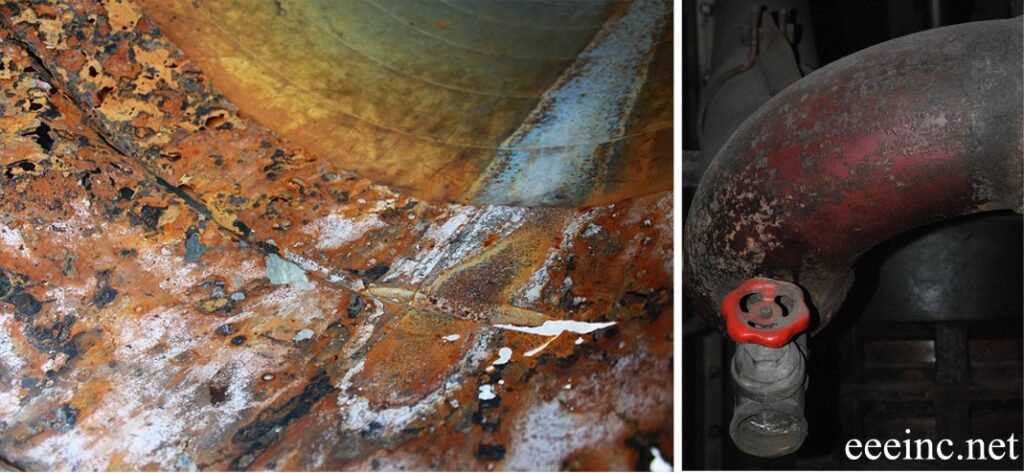

Damage From Feedwater

So, how do scaling and corrosion happen? Insoluble carbonates are form from the carbon dioxide released when magnesium and calcium salts are heated and dissolved in water. These form deposits on the surface of the boiler. The accumulation of these deposits leads to failure of tube functioning due to overheating. Efficient transfer of heat from the tubes to water fails to take place due to the excessive deposit formations. They act as total or partial obstructions in boiler tubes eventually leading to overheating and reduced efficiency.

Corrosion: Low pH levels of water as well as the occurrence of dissolved carbon dioxide and oxygen in the feed water system can cause corrosion. The form of corrosion known as deep pitting can lead to leakage in the tubes of the boiler system. Corrosion that occurs below the boiler deposits leads to tube failure due to the weakening of metal. Essentially, corrosion leads to reduced efficiency by weakening of tubes which can lead to water leakage: a worst case scenario.

The Bottom Line

With 100+ years of combined experience, the technicians at Engineered Energy Equipment have specific experience in some of the most challenging of all feedwater situations: the high seas where ballast water is used.

Kevin Warren, Director of Sales at EEE, became a Boiler Technician in the US Navy, where he became a Chief Petty Officer overseeing the boiler operations of many Navy ships that depended on efficient boilers to transport patriots to wherever our US military was called upon.

With over 100 years of combined experience in the boiler business, the EEE team helps their clients choose the equipment that can weather the storm while producing steam for applications from hospitals to theme parks to factories to distilleries throughout the state of Florida For more information about the manufacturers represented and products provided by Engineered Energy Equipment, go to https://eeeinc.net/products/.